DTF transfer size drives how your design breathes on fabric, influencing visibility, balance, and wearability across tees, polos, and hoodies, and it sets the baseline for every print you plan. To keep expectations aligned, many pros start with a DTF transfer size chart to map common front and back dimensions to each garment, ensuring consistency from one run to the next. When in doubt, focusing on choosing transfer size by garment type, print complexity, and viewing distance keeps projects predictable and scalable, making it easier to satisfy clients and maintain quality. DTF print size by garment helps you balance attention, legibility, and wear, and it pairs with practical DTF transfer placement guidelines to avoid seams, folds, and distortion during heat pressing. Finally, earning reliable results comes from applying DTF sizing tips, testing on representative samples, and documenting decisions so teams can reproduce the same look across orders.

Beyond exact measurements, the topic also hinges on how much space your artwork occupies on a given garment, commonly referred to as the print area or canvas. Think of it as the visible footprint on the fabric—the portion of the surface where color, detail, and contrast need to stay clear and sharp. In practical terms, designers consider placement, scale, and readability at typical viewing distances, as well as how the transfer interacts with seams, collars, and fabric stretch. By framing the concept as an application zone or design footprint, you can optimize aesthetics while preserving durability and wash-fastness across products.

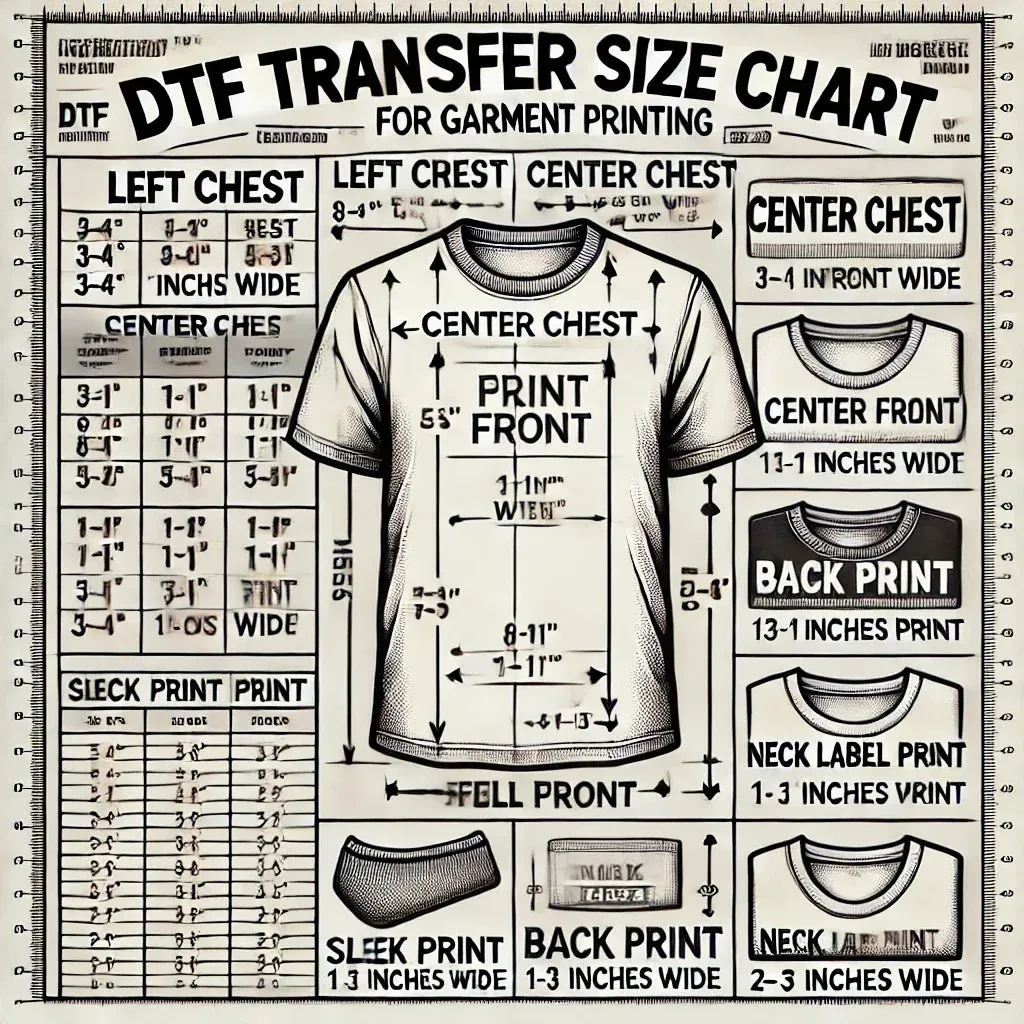

Understanding the DTF Transfer Size Chart: Read, Compare, and Choose

A DTF transfer size chart serves as a practical reference that maps design dimensions to garment canvases. It helps you forecast how a given artwork will appear on different products and guides you in the process of choosing transfer size with clarity. By aligning art proportions to garment front area, you can balance visibility, readability, and wearability from the first sample to the final run. Using the chart also supports informed conversations with customers about what size will best showcase their logo or artwork.

When you approach the DTF transfer size chart, focus on proportion and context. Compare your design’s bounding box to the chart intervals, and consider margins, seams, and potential folding points. This is where distance, legibility, and mass appeal come together, reinforcing how a thoughtful size choice contributes to long-term satisfaction and reduced reprints. For ongoing optimization, integrate DTF sizing tips into your workflow so each new product line starts from a tested, repeatable standard.

Choosing Transfer Size for T-Shirts and Hoodies

Front prints on adult tees typically benefit from a balance between presence and wearability, often landing in the 8×10 to 12×14 inch range. Hoodies, with their larger canvases, can accommodate bigger accents, commonly 9×12 inches or more, while keeping important elements away from cuffs and pockets. In both cases, refer to the DTF print size by garment approach to tailor the design to the available front area without crowding necklines or seams.

For youth shirts and lightweight tops, scale down to preserve readability, often 4×4 to 5×7 inches for the front and 6×8 inches or smaller for back placements. When it comes to caps or bags, the rules differ due to curved surfaces and smaller extents, so you’ll apply different sizing logic while still aiming for legibility and design integrity. Throughout, keep in mind that choosing transfer size should align with customer goals and product expectations.

DTF Print Size by Garment: Matching Art to Canvas

Different garments present distinct canvases, so translating a design from screen to fabric means respecting each garment’s unique real estate. For a full-front tee, you might push toward larger sizes to achieve visual impact, while a chest logo benefits from a compact footprint to maintain subtle branding. The principle of DTF print size by garment is to maximize clarity on the surface you’re decorating, not merely to apply a one-size-fits-all solution.

Always evaluate how the design reads at typical viewing distances and in motion. A large, multi-color piece may require simplification or segmentation into multiple transfers to preserve legibility. By understanding how size interacts with color density and fabric texture, you can preserve sharp edges and vibrant color even as the garment changes shape with wear.

DTF Transfer Placement Guidelines: Position, Balance, and Durability

Placement plays a critical role in aesthetics and performance. Chest logos, center-front prints, and back designs each have recommended size ranges and preferred distances from seams or necklines to maintain balance. Following the explicit insight of DTF transfer placement guidelines helps ensure your artwork sits correctly, avoiding distortion or cracking when the wearer moves.

Beyond initial placement, consider fabric weight, stretch, and garment construction. Dark fabrics may require slightly larger or higher-coverage transfers to maintain visibility, while light fabrics can preserve contrast with careful color choices. Respect margins from edges and seams to prevent cracking and to keep the design looking fresh through repeated wear and washing.

DTF transfer size: Practical Tips for Consistency

Consistency begins with a repeatable sizing framework. Create templates for each garment type, map safe print areas, and lock in recommended size ranges to minimize confusion across product lines. Document the rationale behind each size choice so sales, design, and production teams stay aligned—and so customers get predictable results.

Leverage a catalog of scale-aware designs, and ensure your designs translate well across sizes by testing on representative samples. Implement a standard measurement approach, and maintain a simple, reusable process for adjusting sizes when needed. Regularly review and refine the chart to reflect product newness, fabric updates, or changes in customer expectations.

Measuring, Mock-Ups, and Testing for Consistent DTF Results

Begin by defining the design’s bounding box and comparing it to your mock-up on a representative garment. If a design looks oversized on a smaller size, scale down while preserving key elements. Visualize the print in life-size terms on the wearer to anticipate how it will sit when active and moving.

Create a robust testing process that includes mock-ups, test transfers on similar fabrics, and a wash-and-wend test to assess colorfastness and durability. Use the results to fine-tune margins, placement, and size. A disciplined testing workflow reduces reprints, boosts customer confidence, and sustains product quality across new lines and seasonal collections.

Frequently Asked Questions

How do I use a DTF transfer size chart to determine the right transfer size?

A DTF transfer size chart provides baseline ranges by garment size and design type. Start with the garment size (youth, adult tee, hoodie), choose the design category (logo, full-front, back), and pick a size within the recommended range (e.g., 4×4 for small logos up to 12×16 for full-front). Always verify proportions on a mock-up and maintain margins of about 0.25–0.5 inches.

What factors influence choosing transfer size for different garments?

Factors include garment type and size, print complexity, placement goals, fabric color, stretch, and production constraints. Use DTF sizing tips to select a size that preserves readability and balance; highly detailed graphics may need size reductions for smaller garments.

What is the recommended DTF print size by garment for a chest logo on an adult tee?

For chest logos on standard adult tees, aim for about 4×4 to 6×6 inches. For bolder branding, 6×6 to 8×8 inches can work if clearance from the neckline is respected and mock-ups look balanced. For full-front designs, sizes like 8×10 to 12×14 inches apply.

How do DTF transfer placement guidelines affect the ideal transfer size on shirts and hoodies?

Placement guidelines specify safe distances from collars, hems, and seams to preserve legibility as the garment moves. Chest logos typically stay 3×3 to 6×6 inches, back designs 8×12 to 12×16 inches; adjust size to match the garment canvas and avoid seams.

What are common mistakes to avoid when sizing DTF transfers?

Common mistakes include assuming bigger is always better, neglecting margins near edges, ignoring fabric limitations, and skipping tests. Follow DTF sizing tips to maintain readability, durability, and wash-fastness.

How should I measure, test, and finalize the DTF transfer size before full production using a DTF transfer size chart?

Start with the design bounding box, create a mock-up, check readability from 3–6 feet, and ensure margins of 0.25–0.5 inches. Run a test transfer on similar fabric to confirm color and durability, and use a DTF transfer size chart to ensure the size scales well across garment sizes before the full run.

| Aspect | Key Points |

|---|---|

| What is DTF transfer size? | DTF transfer size refers to the printable area on the transfer sheet that will be applied to the garment. It’s the most critical factor in ensuring your design appears as intended. A poorly sized transfer can look oversized on a small garment or appear tiny and lost on a large canvas. A well-chosen DTF transfer size balances aesthetics, readability, and the garment’s dimensions. Units are inches or centimeters. Typical sizes range from compact 4×4 inch logos to expansive 12×16 inch full-front designs for adult tees and hoodies. |

| Why DTF transfer size matters | DTF transfer size affects visibility, balance, and wearability. It influences how well details read from a distance and whether the design sits proportionally on the garment. |

| DTF Size Chart: Practical Reference | Here’s a practical starting point you can adapt based on garment type and customer preference: |

| • Youth/Children’s shirts and small sizes | 4×4 to 5×7 inches; • Small to medium adult tees: 6×8 to 7×10 inches; • Medium to large adult tees: 8×12 inches; • Tops with larger canvases (unisex hoodies, jackets): 9×12 to 12×14 inches; • Full-front designs for adult tees or hoodies: 12×16 to 12×20 inches; • Caps and Hats: 2×3 to 3×4 inch area; • Totes and Accessories: 6×8 to 9×12 inches. |

| Key Factors That Influence Transfer Size | • Garment type and size: Tiny children’s sizes require smaller prints; adult sizes can accommodate larger designs. • Print complexity: Highly detailed or multi-color graphics may need to be reduced in size for readability. • Placement goals: Chest logos, center-front, and back designs each have recommended ranges to maintain balance (e.g., chest logo 3×3–6×6 inches; back designs 8×12–12×16 inches). • Garment color and fabric: Dark fabrics may need larger or higher-coverage transfers for visibility; light fabrics require contrast considerations. • Fabric stretch and integrity: Large transfers on stretch fabrics can peel/crack if not sized properly. • Production constraints: Heat press time, transfer thickness, and color count can limit practical maximum size. |

| Choosing the Right Size for Common Garments | Shirts (Adult): Front print around 8×10 to 12×14 inches for balance; bolder look 12×12 to 12×16 inches. Ensure clearance from the neckline (about 2–3 inches below the collar). Chest logo around 4×4 to 6×6 inches. Shirts (Youth/Children): 4×4 to 5×7 inches for chest-front; back designs 6×8 inches or smaller. Hoodies and Sweatshirts: Front 9×12 inches; 12×14 inches for bolder; Back designs 12×16 inches; place away from seams/pockets. Caps and Hats: 2×3 to 3×4 inches; simplify complex artwork due to curvature. Totes and Accessories: 6×8 to 9×12 inches for strong visual impact. |

| How to Measure and Set the Right Size on Your Design | 1) Start with the design’s bounding box. If larger, scale down while preserving key elements. 2) Place the design on a garment mock-up to verify proportion. 3) Use a sizing checklist: readability from 3–6 feet away, important details not lost near seams, sits below the collarbone. 4) Consider margins: leave at least 0.25–0.5 inches from garment edges to prevent cracking or peeling. 5) Test print: run a test transfer on similar fabric to confirm color accuracy and durability before a larger run. |

| Special Considerations for Fabric and Garment Styles | • Dark vs light fabrics: color contrast matters; you may need a larger size on dark fabrics for legibility. • Fabric weight and stretch: lighter fabrics may stretch more, so slightly smaller sizes can prevent distortion. • Garment seams and placement: avoid printing too close to seams, hems, or fold lines. • Multi-panel designs: if the print spans a torso/shoulder seam, size choices must account for potential misalignment as the garment moves. |

| Practical Tips for Consistent Results | • Use a standard measurement approach across products to improve consistency. • Keep a reusable template for each garment type mapping safe print areas and recommended sizes. • Build your catalog with scale-aware designs; if a size must be fixed, test on representative samples. • Document size decisions to aid sales and production teams. |

| Common Mistakes to Avoid | • Bigger isn’t always better; large prints can overwhelm smaller garments and reduce readability. • Overlooking margins near edges; prints too close to collars, hems, or seams are prone to cracking. • Ignoring fabric limitations; heavy designs on delicate fabrics may crack or peel faster. • Skipping tests; without a sample run, you can’t reliably predict washing/wear outcomes. |

Summary

Conclusion